+86-18628829666

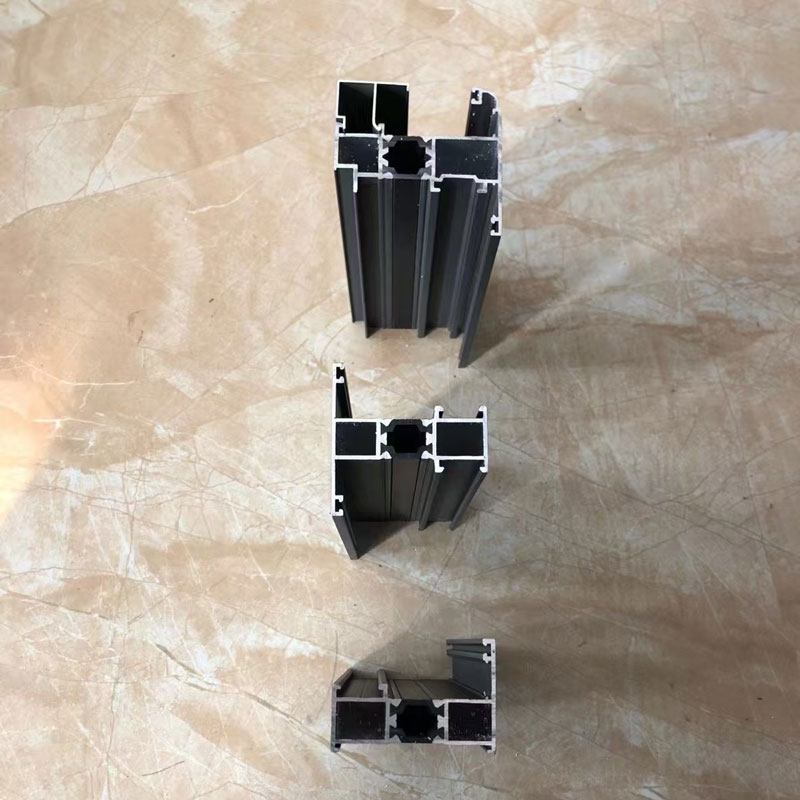

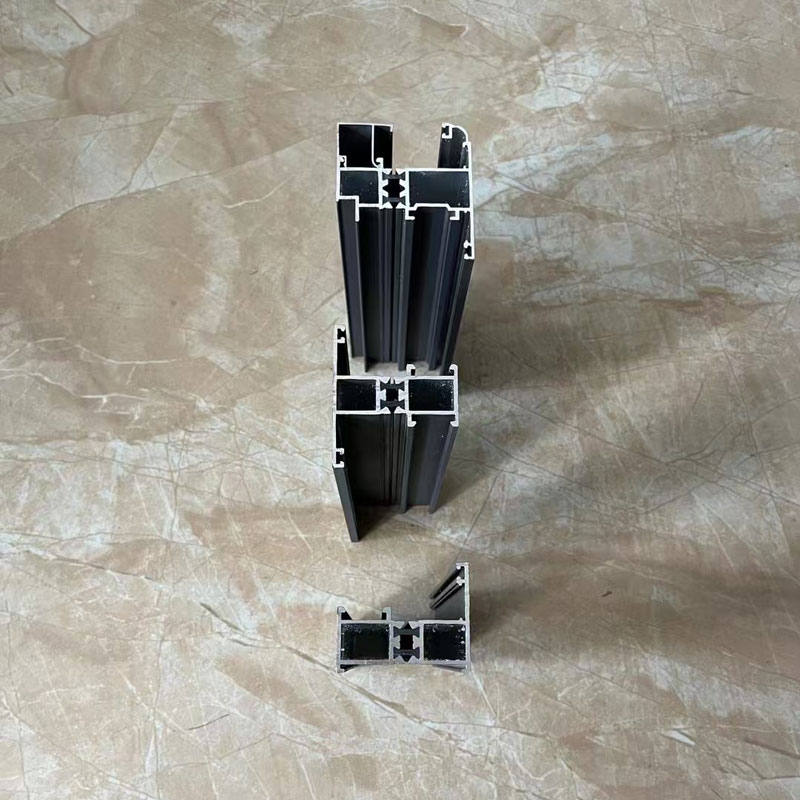

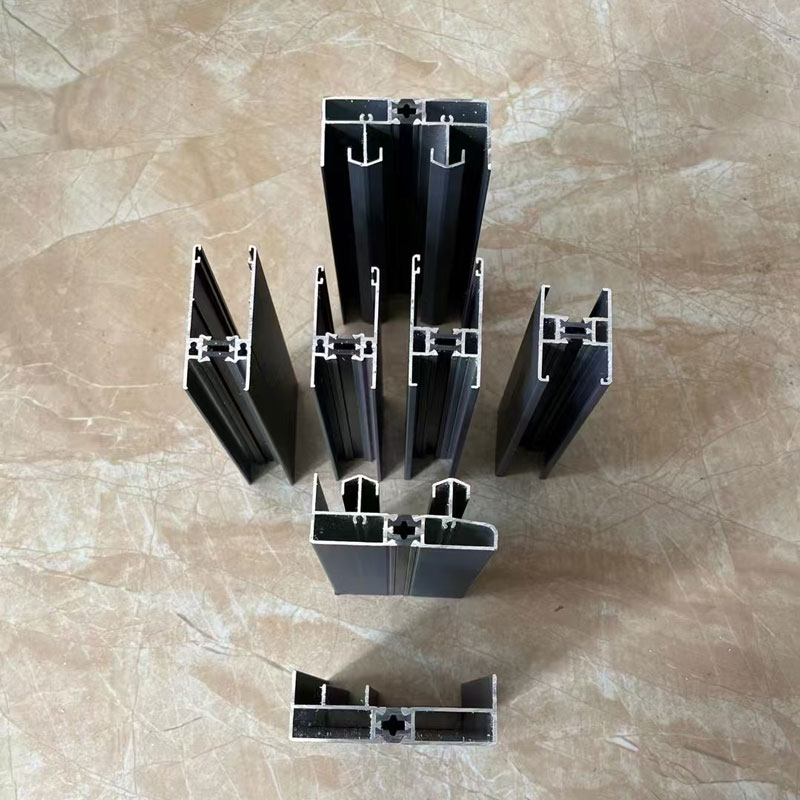

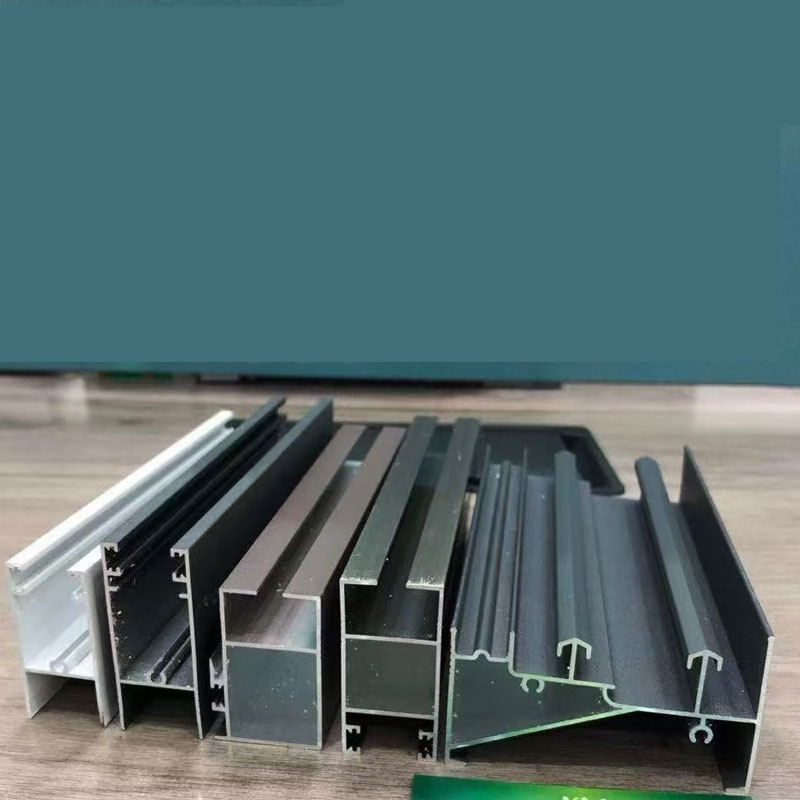

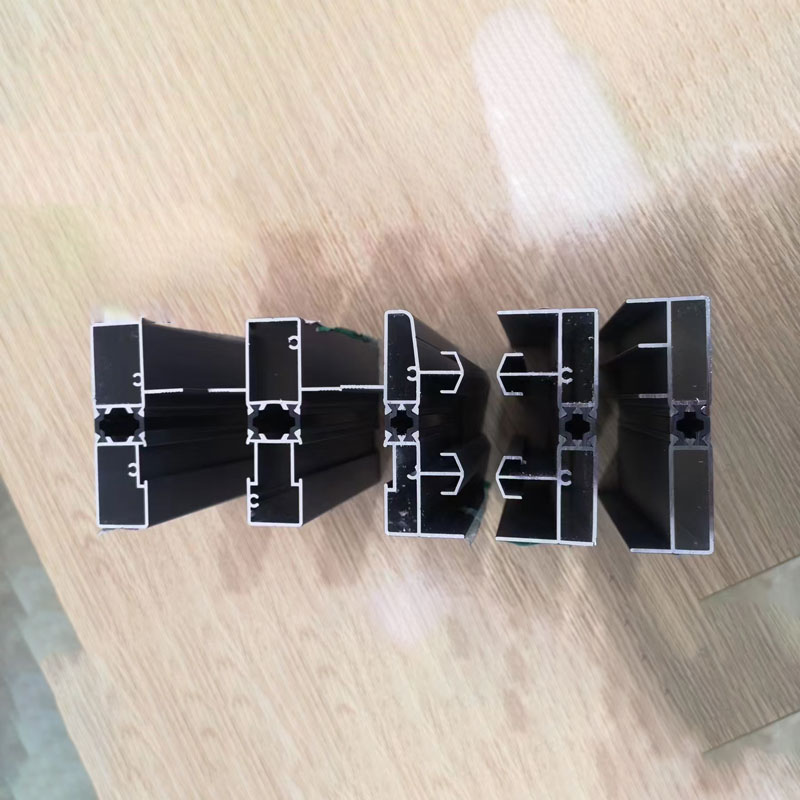

Aluminum alloy profile

Aluminum alloy profile

Aluminum alloy profiles are a popular and universal building material that finds use in various fields. Lightness, strength and durability - these are the main advantages that make this material so popular.

A variety of forms and applications

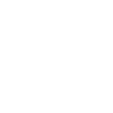

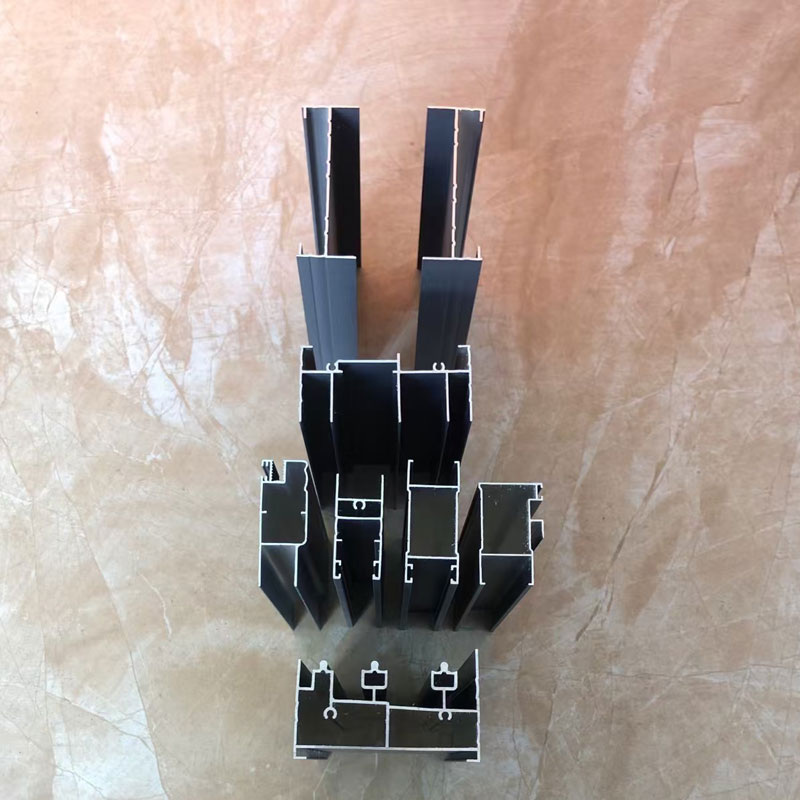

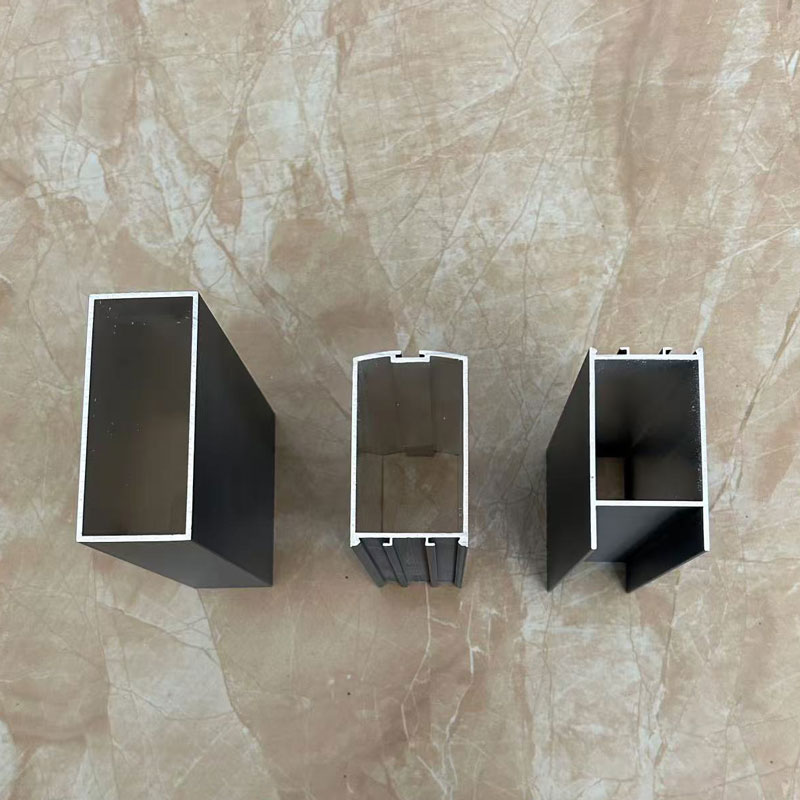

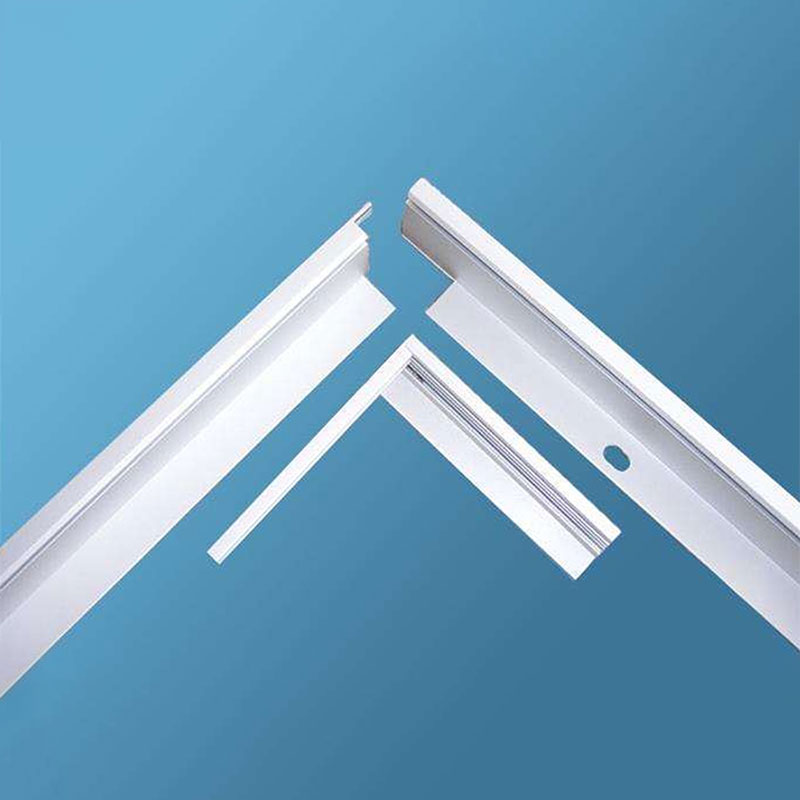

Aluminum profiles are available in a wide range of forms and sizes. These can be thin stripes for decorative elements, powerful beams for frames, or complex three -dimensional structures for window and door systems. Due to its flexibility, from them you can create almost any geometric shapes, from simple rectangles to elegant curves. They can be used in architecture, in the manufacture of furniture, in sports equipment, and even in the creation of models. Imagine a light, but solid staircase made from such profiles - this is one of the many examples.

Advantages over other materials

Aluminum profiles are won in comparison with analogues made of wood or steel. They are much easier to steel, which reduces the load on the supporting structures. The tree, of course, is also a light material, but aluminum profiles are much more resistant to moisture and decay. This factor makes them an ideal choice for external work and in conditions of high humidity. Profiles are also characterized by high corrosion resistance, which significantly increases their service life. This is especially true, if we talk about use in the open air or in aggressive environments.

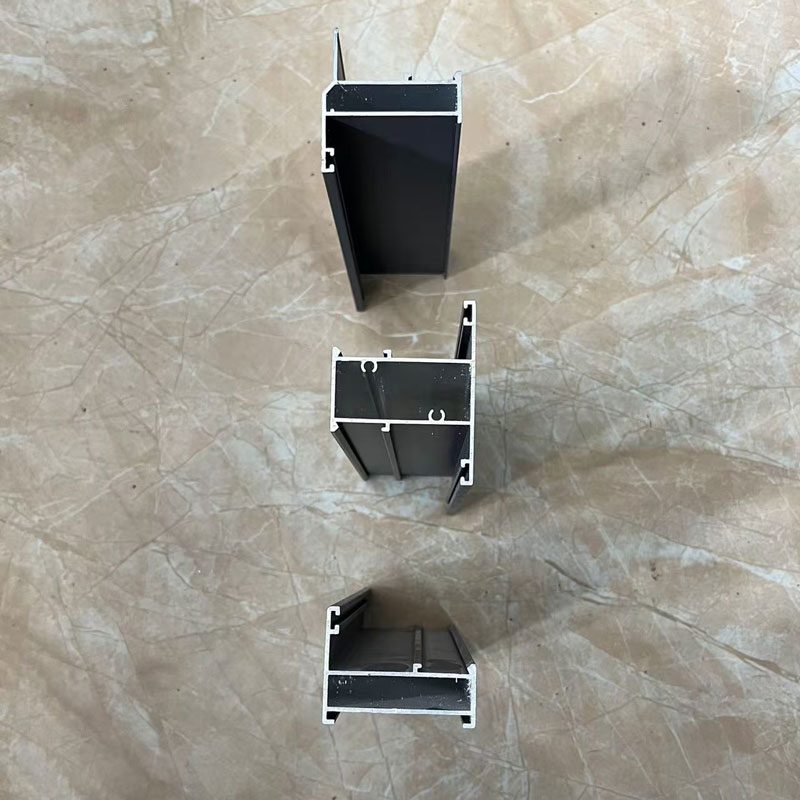

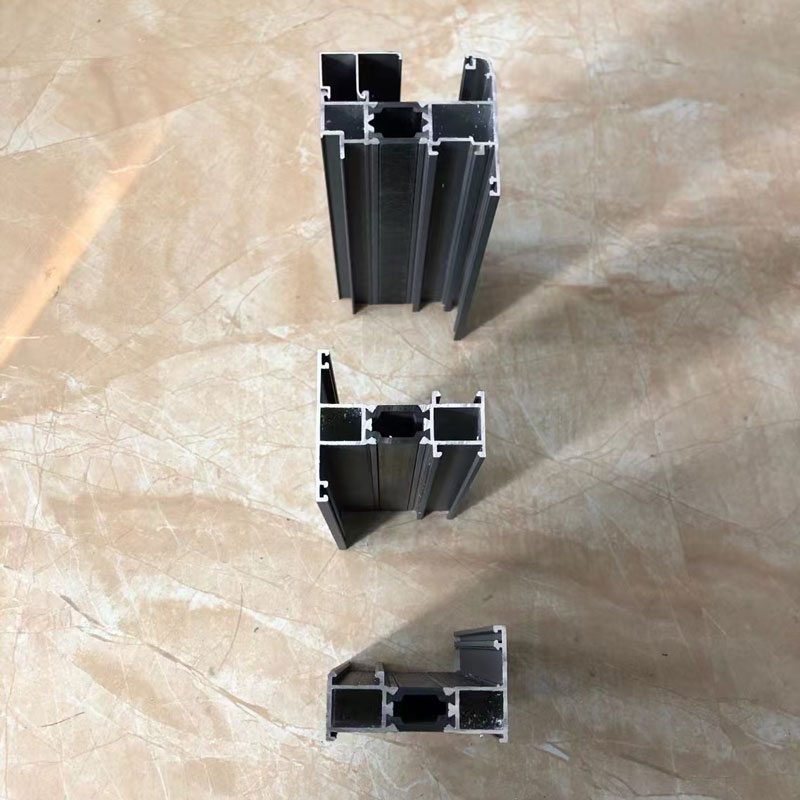

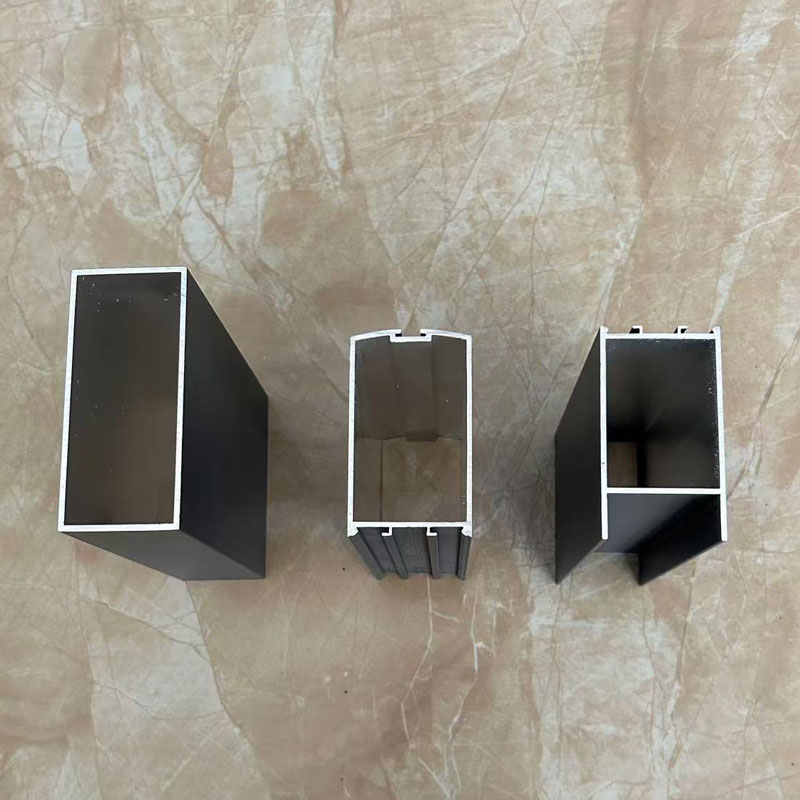

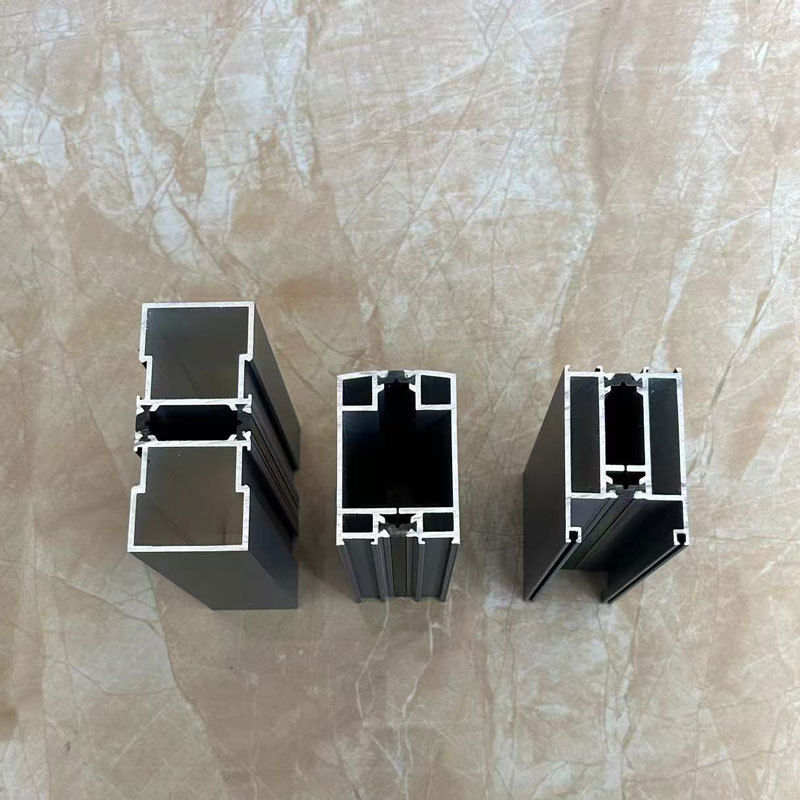

Production technologies and quality

Modern production technologies allow you to create profiles with high accuracy and reliability. The quality of aluminum alloys plays a key role in the final result. The strength, durability and resistance to external influences depend on this. A good profile should be even, smooth and have clear geometric parameters. This provides an ideal docking of details, which is important for aesthetics and long construction service. It is clear that quality control at all stages of production is the key to creating reliable and durable profiles.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling products-

88 Jianu is sliding

88 Jianu is sliding -

New 50 is sash

New 50 is sash -

Industrial material-religious products

Industrial material-religious products -

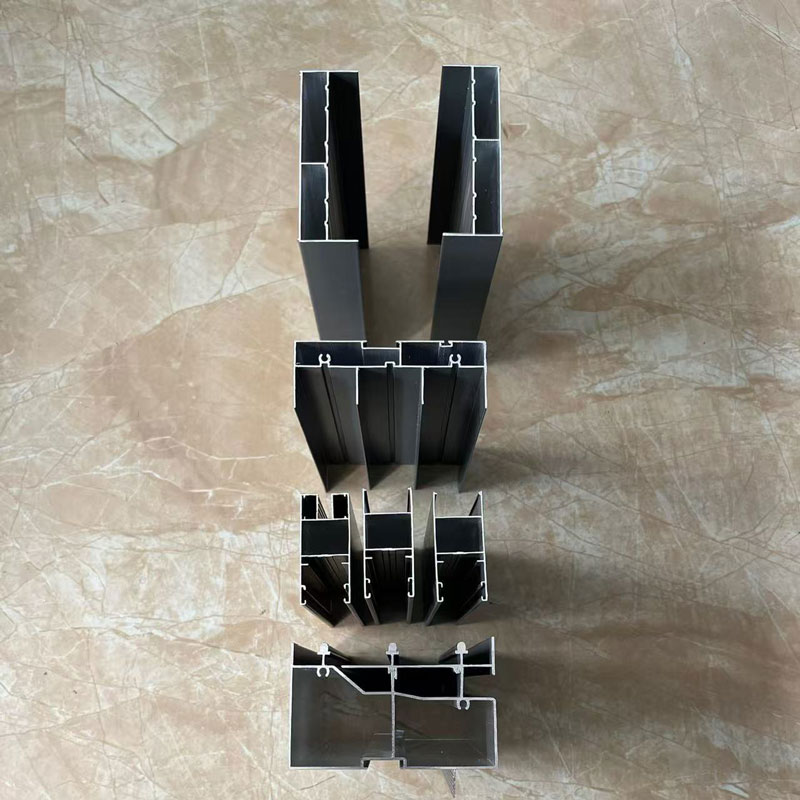

90 broken bridge and sliding

90 broken bridge and sliding -

65 broken bridge and sash

65 broken bridge and sash -

95 Jianu is sliding

95 Jianu is sliding -

110 yuisha broken bridge

110 yuisha broken bridge -

110 linghane is sash

110 linghane is sash -

Floor spring door

Floor spring door -

Solar energy-nasadar products

Solar energy-nasadar products -

Floor spring door 2

Floor spring door 2 -

Floor spring door with a broken bridge

Floor spring door with a broken bridge

Connectedsearch

Related search- Aluminum profile doors

- built -in aluminum profile

- The price of a flat gap bridge in China

- Cheap aluminum

- Aluminum wall plate

- The price of glass from aluminum profile in China

- The country-buyer of cheap internal sliding doors

- Cheap aluminum tube 32 mm from the manufacturer

- Factory of cheap LED lamps with aluminum profiles

- Chinese manufacturer of built -in aluminum profiles