+86-18628829666

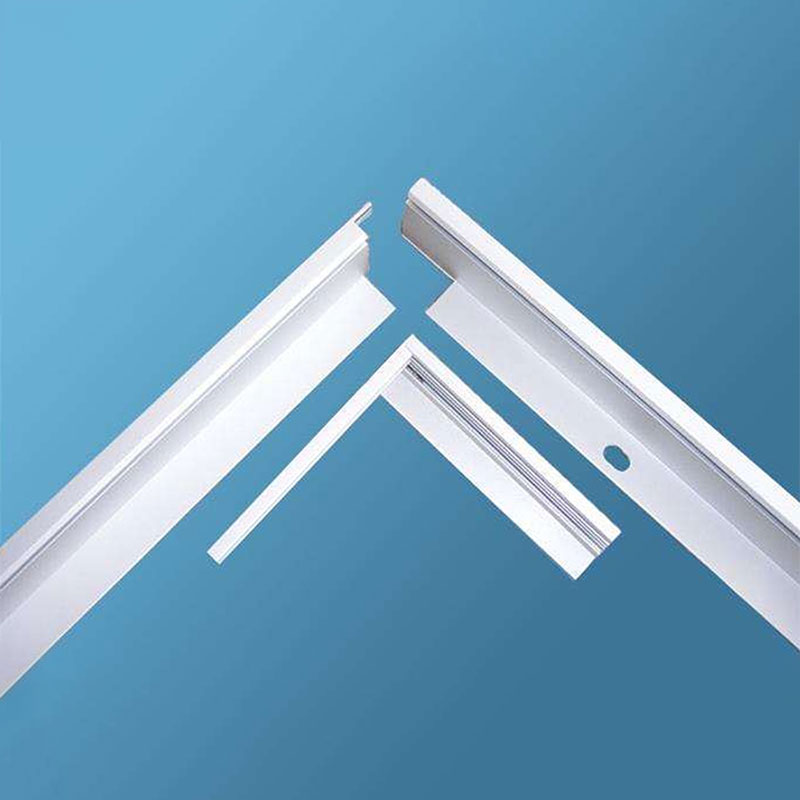

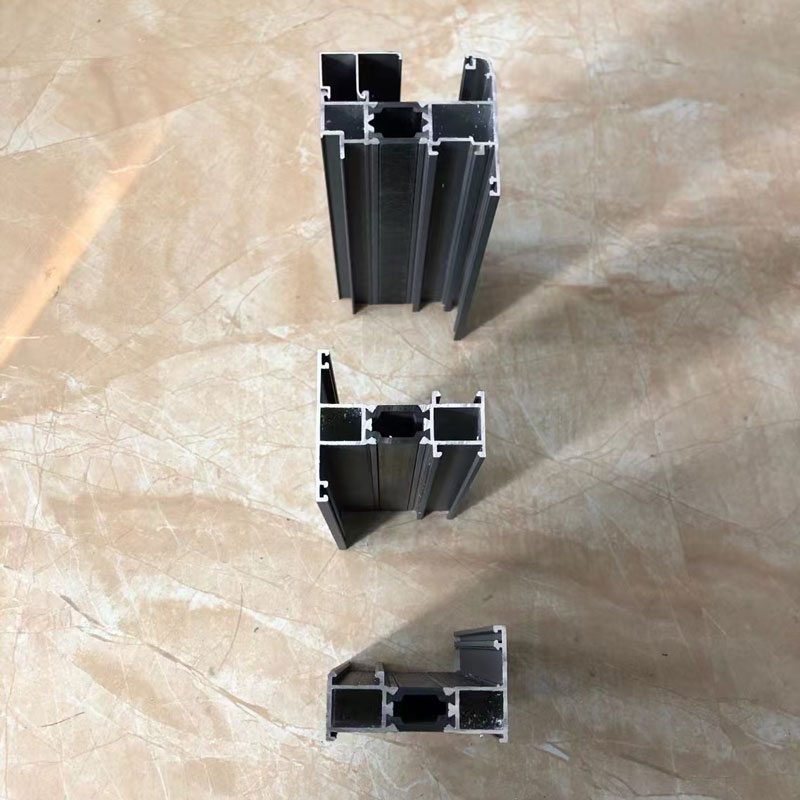

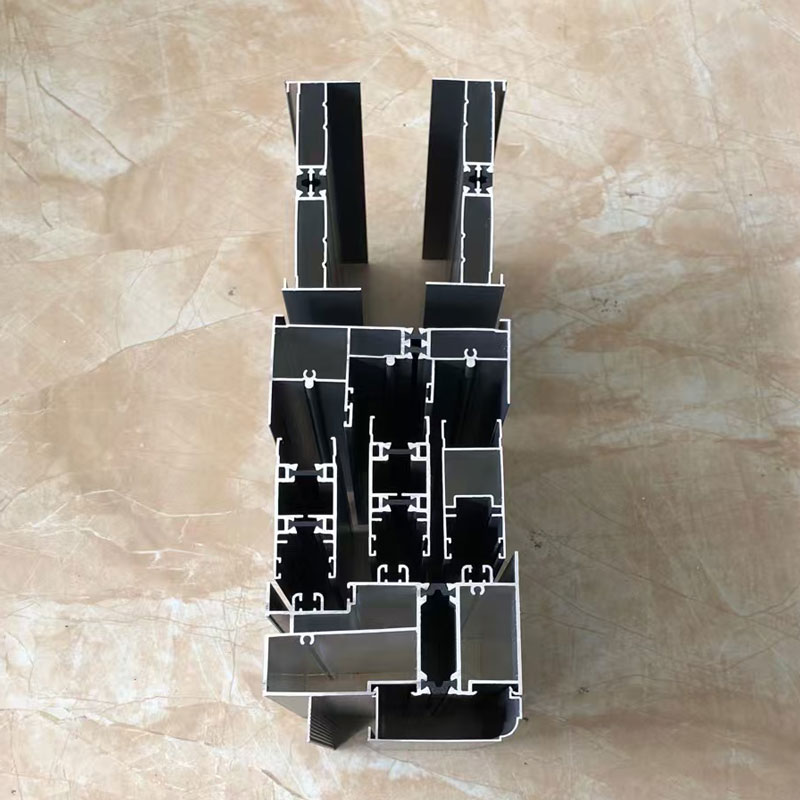

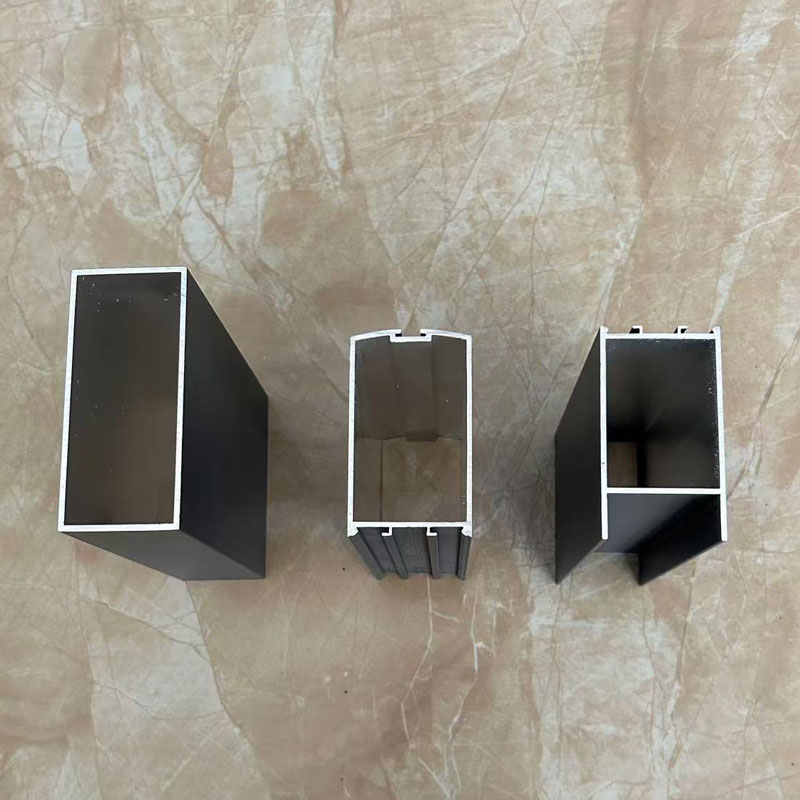

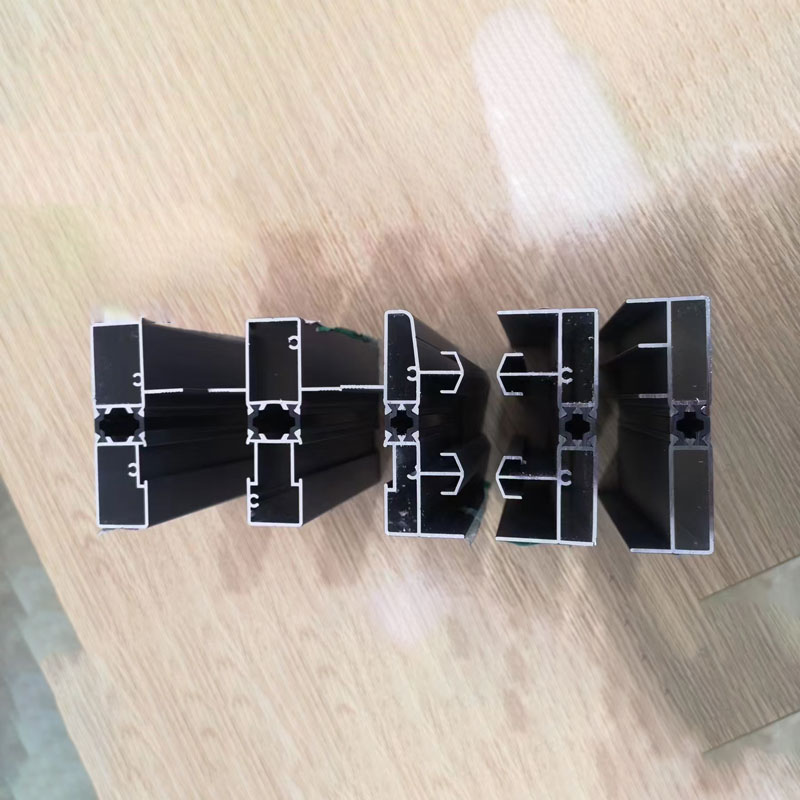

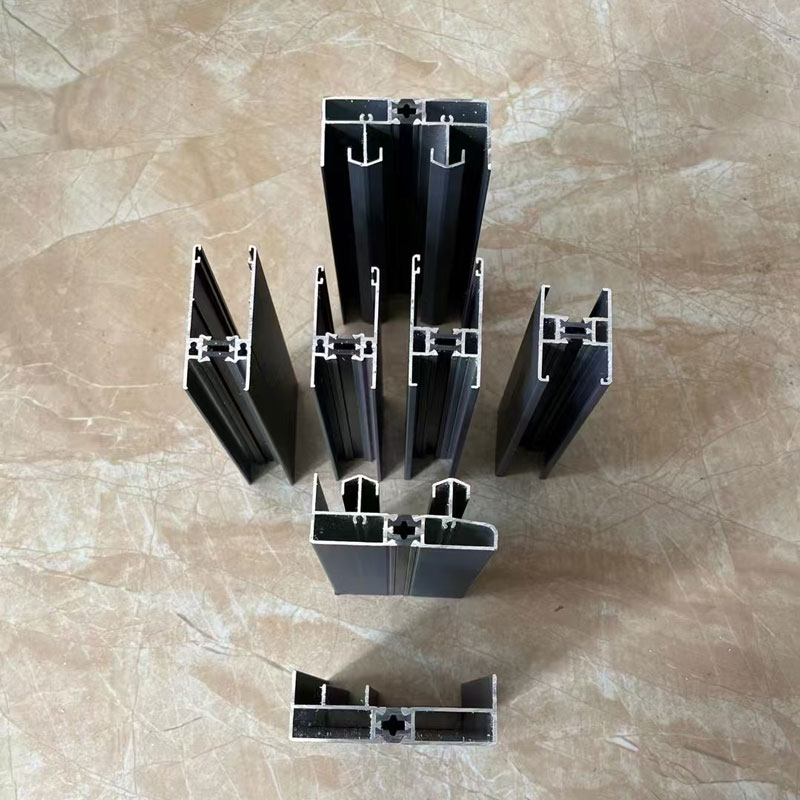

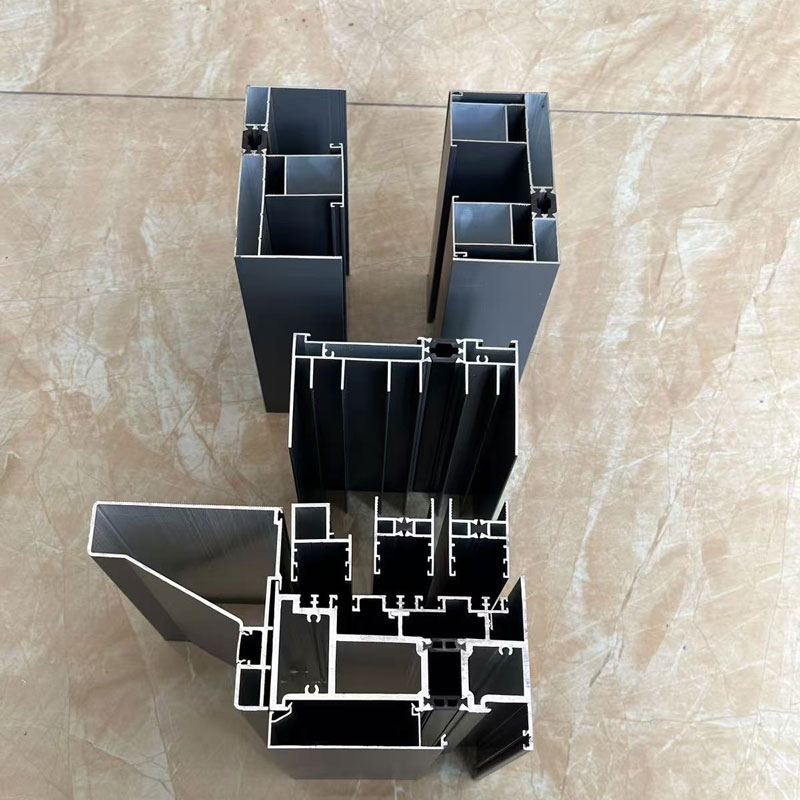

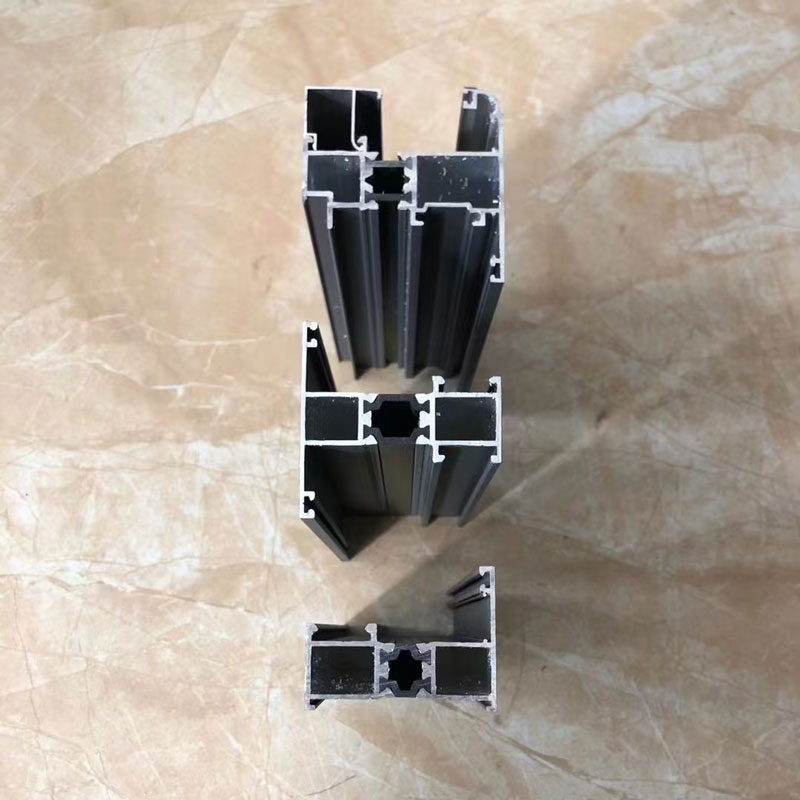

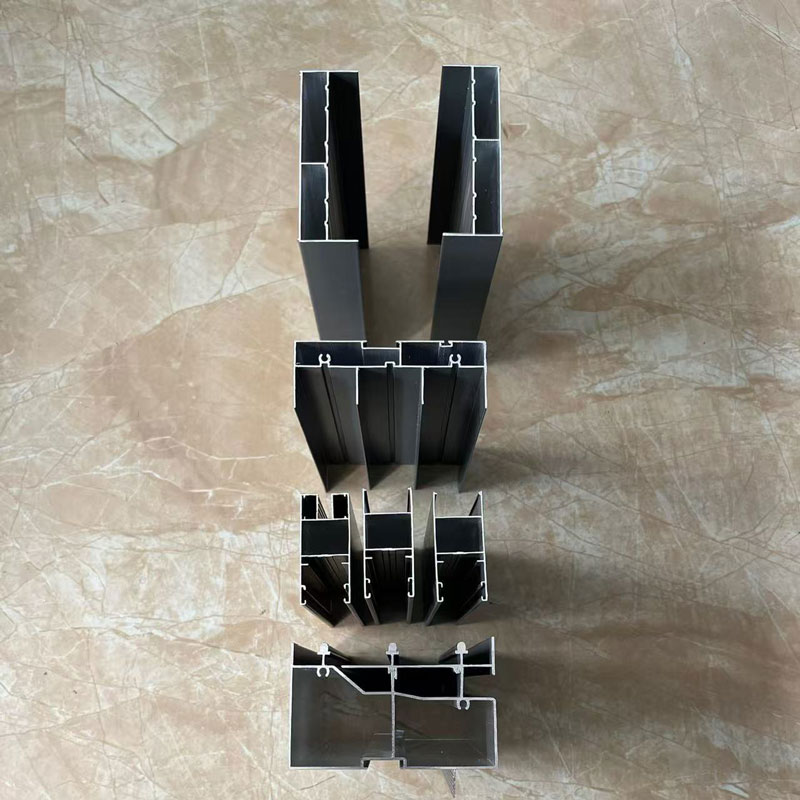

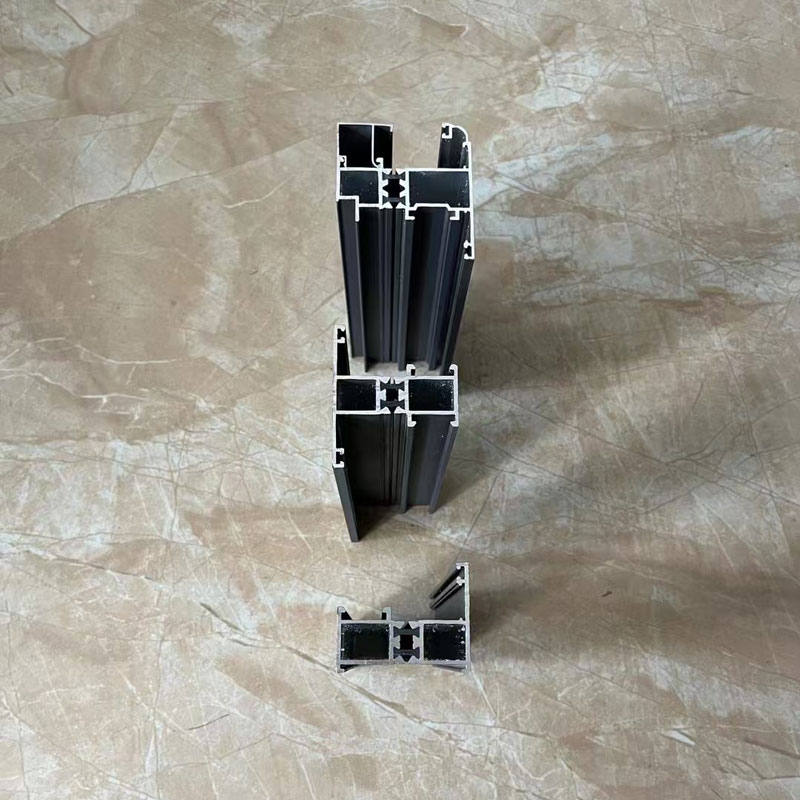

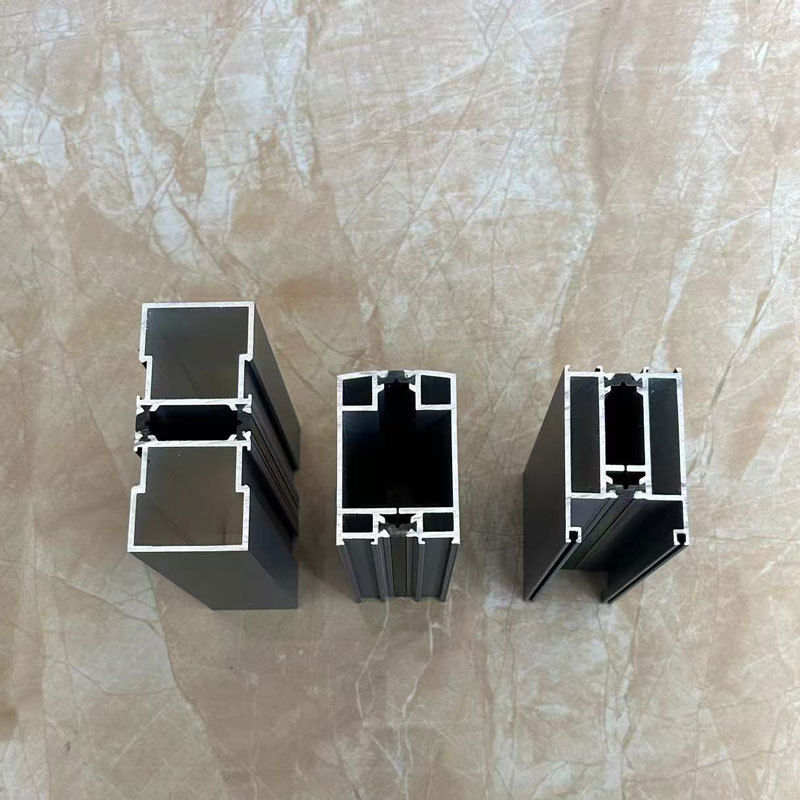

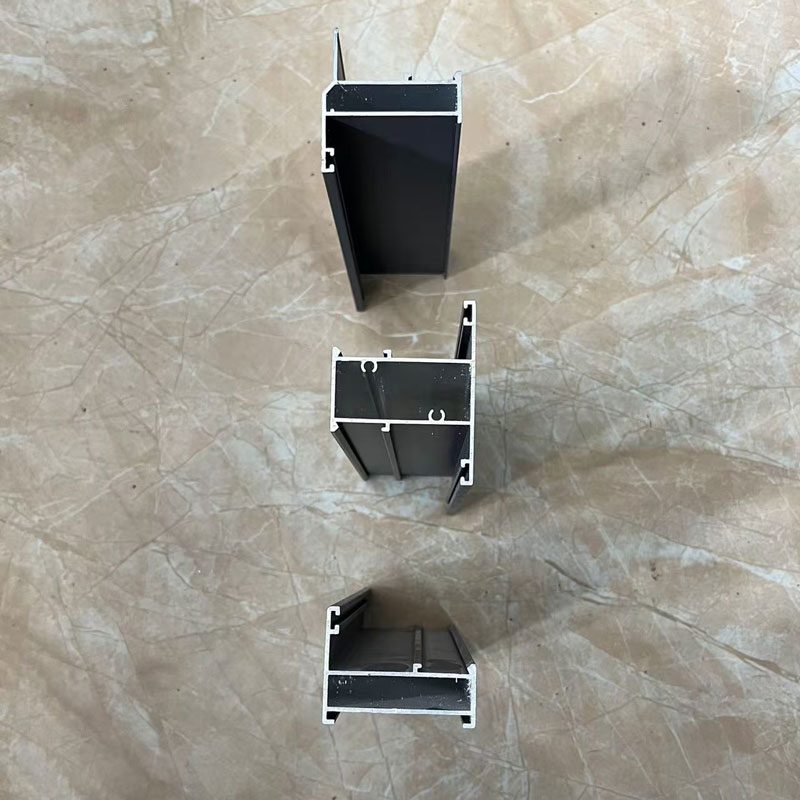

Profile pressed from aluminum alloy

Profile pressed from aluminum alloy

Aluminum alloy profiles are, in fact, blanks that have a certain shape. Imagine a sheet of aluminum, which seems to turn into the part you need, for example, part of the bicycle frame, a lid for a box or even a profile for a window opening. Pressing is a technology that gives it this form under pressure.

Advantages of pressed aluminum profiles

Pressed aluminum profiles have a number of wonderful properties. Firstly, they are light, but at the same time quite strong. This means that the design in which such a profile is used will weigh less, and therefore, consume less energy. The second - they are resistant to corrosion. Aluminum itself is well opposed by rust, which makes it durable material. And finally, pressed profiles are easily processed. This allows you to quickly and accurately create the necessary forms, which is very convenient in production. All this makes them in demand in various industries.

Scope of use of pressed aluminum profiles

The use of pressed aluminum alloy profiles is very wide. They are used in construction, for example, to create light and reliable buildings. In mechanical engineering and automotive industry, these profiles are used for the manufacture of various parts and elements. In household appliances and furniture production, they provide strength and lightness of the structure. Also, pressed aluminum profiles are indispensable in the production of advertising structures, souvenirs and many other products. In general, where a combination of strength, lightness and durability is required, there, as a rule, a pressed aluminum profile is used there.

The choice of a pressed aluminum profile

When choosing a profile, several parameters must be taken into account. The aluminum alloy that determines its strength and resistance to loads is important. An important role is played by the shape and size of the profile, which must meet the specific requirements of the project. It is also important to pay attention to the thickness of the material. The thicker the profile, the higher its strength, but the greater the weight. The combination of these parameters will allow you to choose the best solution for your project. Therefore, when choosing, you should contact specialists who will help you choose the best option.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling products-

108 Jianu Broken bridge and sliding

108 Jianu Broken bridge and sliding -

110 linghane is sash

110 linghane is sash -

Floor spring door 2

Floor spring door 2 -

70 broken bridge and sash

70 broken bridge and sash -

90 broken bridge and sliding

90 broken bridge and sliding -

85 broken bridge and sliding

85 broken bridge and sliding -

120 linghana panoramic sliding window

120 linghana panoramic sliding window -

55 broken bridge and sash

55 broken bridge and sash -

95 Jianu is sliding

95 Jianu is sliding -

50 broken bridge and sash

50 broken bridge and sash -

Floor spring door with a broken bridge

Floor spring door with a broken bridge -

New 50 is sash

New 50 is sash

Connectedsearch

Related search- Leading country-buyer of sliding doors for sheds in China

- Chinese supplier of trunk on the roof of the car

- Suppliers of sliding window glass in China

- Cheap price of a mosquito net on a sliding window

- Suppliers of cheap aluminum beams

- The price of aluminum accessories in China

- Chinese aluminum pipe 60 price

- Cheap prices for sliding windows without a bridge

- Aluminum siding manufacturers in China

- cheap aluminum tube 1 supplier