+86-18628829666

A new production line of deep processing of photoelectric materials, creating a new chapter

2024-11-20

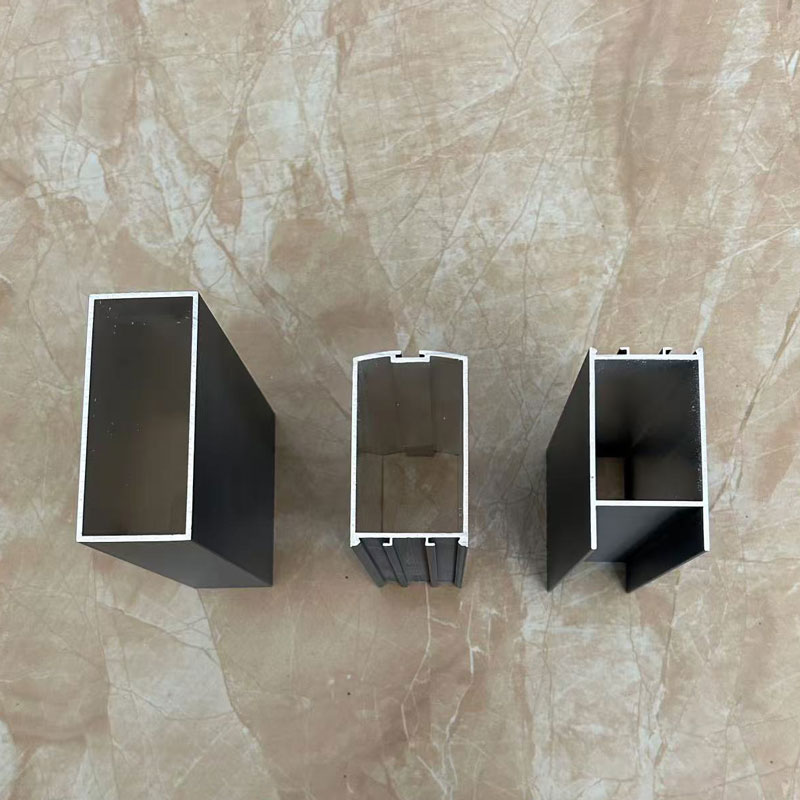

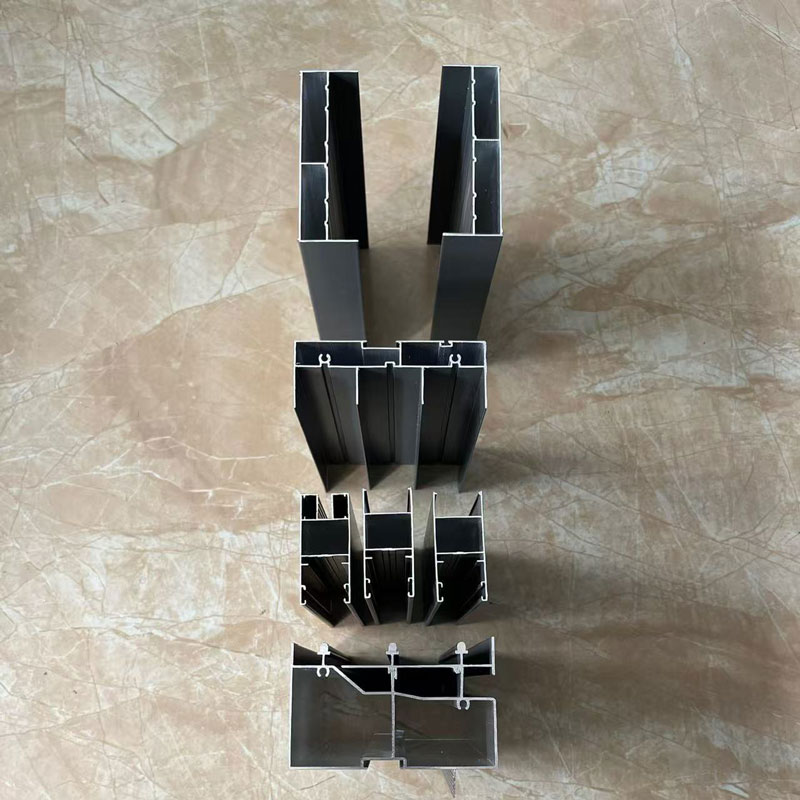

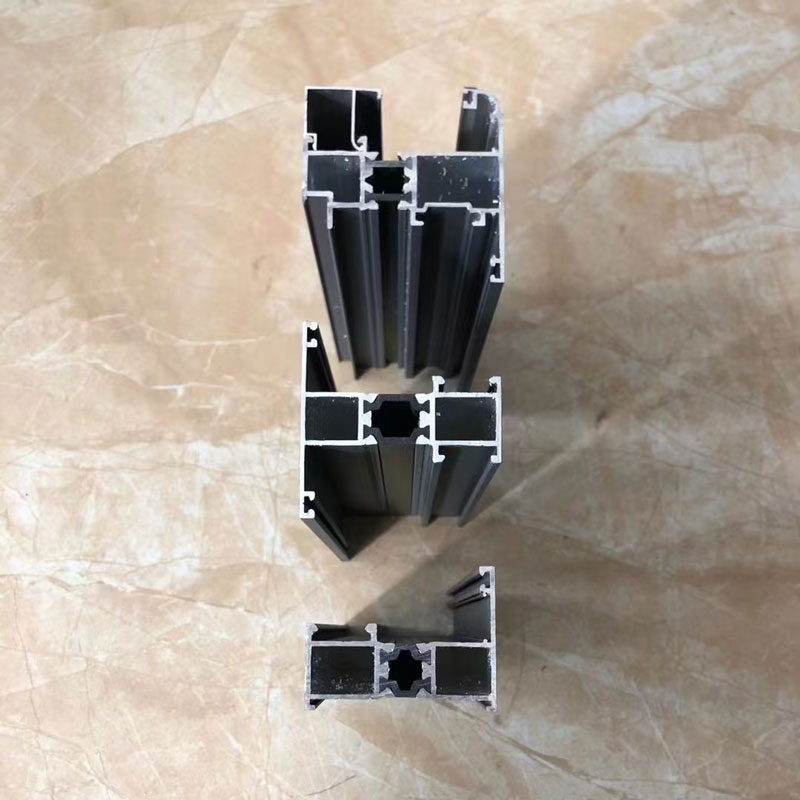

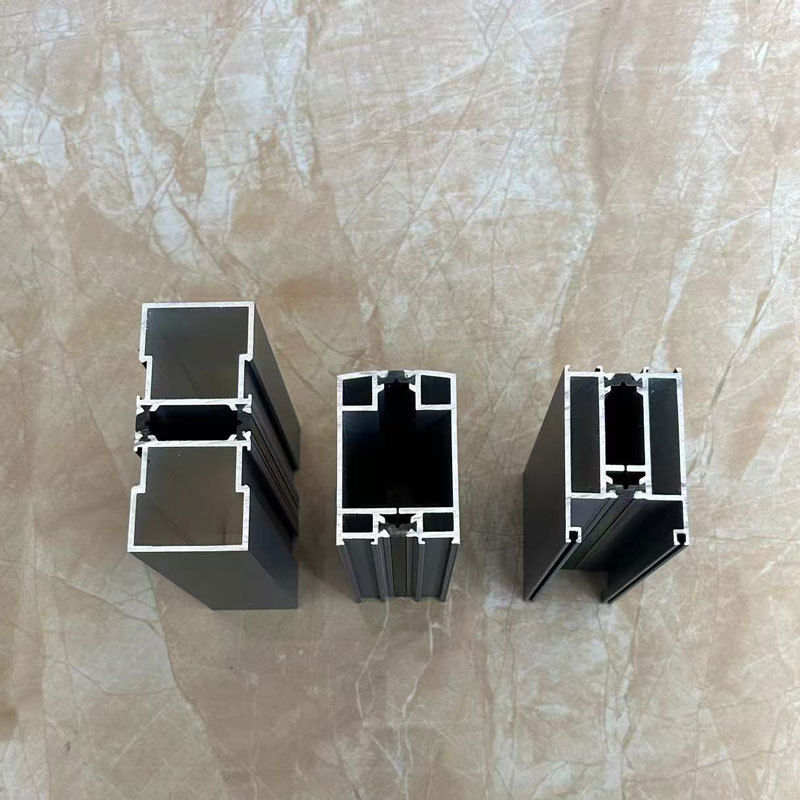

In February 2023, the company again invested in 2 production lines for the manufacture of rims. It is used to process frames for solar panels. To date, the company can operate on the entire assembly line from extrusion to a rim. Also from the plant for processing docking frames directly to the transformation of the plant for the production of docking modules.

In recent years, the solar energy industry has been experiencing rapid growth. In addition to the influence of the general environment, but also inseparable from the state in the sustainable development of the industry on the way to leadership. As a slogan for the “practical work on the development of the state, the industrial restoration of the country”, the new king of the aluminum industry also respond to the call of the country, in a stable, processed green carbon industry, to add bricks and solution.

At a different level, the company on the new processing line is an improvement in the overall product, the customer can be wider in the client. It is also not limited by the frame of the processing plant, which can more effectively compress the cost and strengthen competitiveness in the market.

When choosing models, the company stopped on a fully automated CY850HS processing line, only 6 people can serve the line compared to most frame factories that are now using a manual line of 14 people to save 8 people. This is a big savings in labor. The operators were prepared for work, inspectors are also to work, looking forward to deep processing of the workshop for subsequent actions for the company to create more advantages and opportunities!