+86-18628829666

Zero tolerance for quality problems

2024-11-20

In order to improve the quality of products, improve the efficiency and enthusiasm of employees, strengthen the sense of responsibility of members of the department and strengthen the central -powerful power of the enterprise, our company held the “Monthly of quality” event in September 2024, under the leadership of the company's management, each workshop attached great importance to this event and carried out a thorough organization and strict requirements. Under the leadership of the company's management, each workshop attached great importance to this event, held a thorough organization and fulfilled strict requirements.

1. The completion of the leadership and a thorough organization.

For a more efficient promotion of the activities of the month of quality, the company conducted a meeting of the entire leadership in order to mobilize activities. At the meeting, the goals and requirements for the conduct of a month of quality were briefly explained, as well as officially announced the beginning of its implementation. The specific details of the implementation of measures within the framework of the month of quality, the organization of events and other topics were discussed briefly and in detail. At the same time, clear requirements were put forward to improve the work of each seminar, which marked the official opening of the quality month. The company asked to use the possibility of holding events within the framework of the quality month to create a good atmosphere "everyone pays attention to quality, everyone pays attention to quality."

2. To maintain work on training.

In the framework of this “month of quality”, we successfully stimulated the enthusiasm of our employees to study the quality, increased their awareness of quality and understanding of the importance of quality. In each workshop, a variety of teaching methods for systematic training of employees were adopted, including practical guidance and demonstration, emphasizing the importance of self -control of employees and strict requirements for quality control of parts; At the same time, special training was carried out properly the use of measuring instruments. Adhering to the systems of regular meetings, we continue to strengthen the consciousness of our employees in the field of quality. At the end of each production day, quality inspectors make up a detailed report on the state of production and the quality of products per day, which is regularly published in the workshop, thereby contributing to a significant increase in the general level of quality in the workshop.

3. STRICTION OF PRODUCTION CONTROL PRODUCTION CONTROL

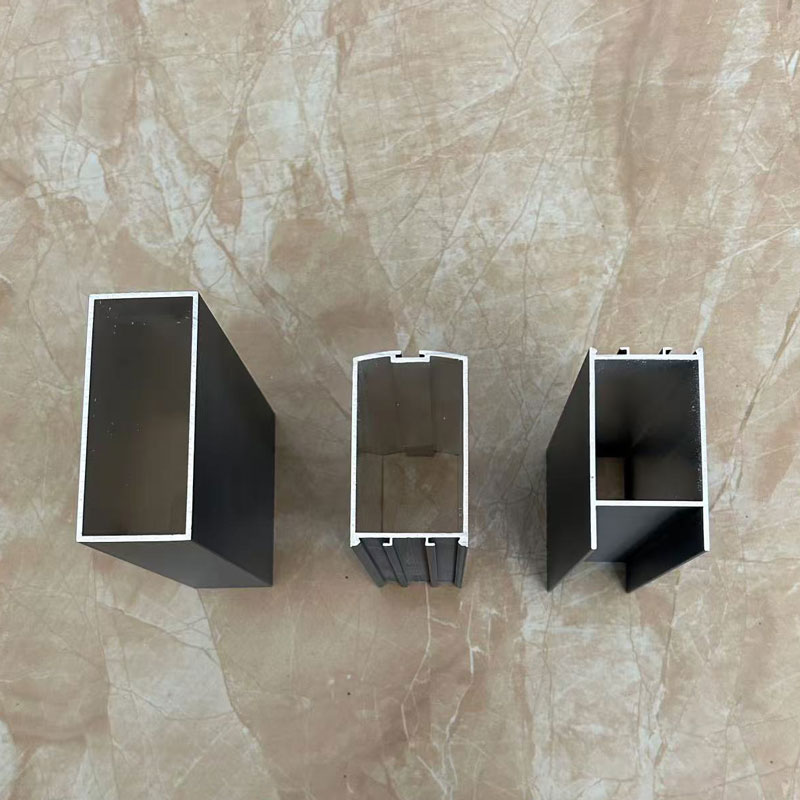

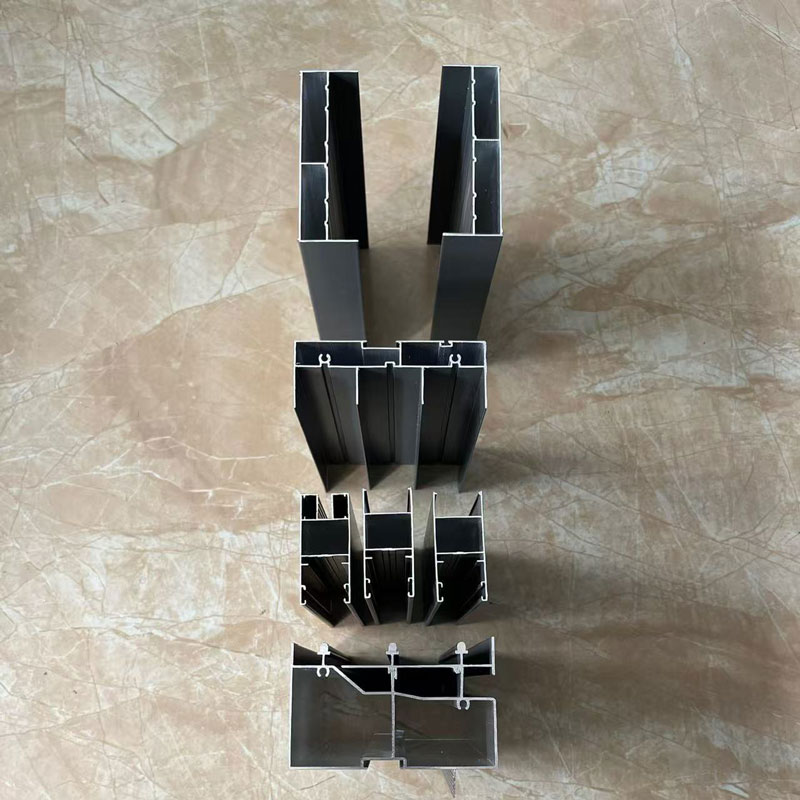

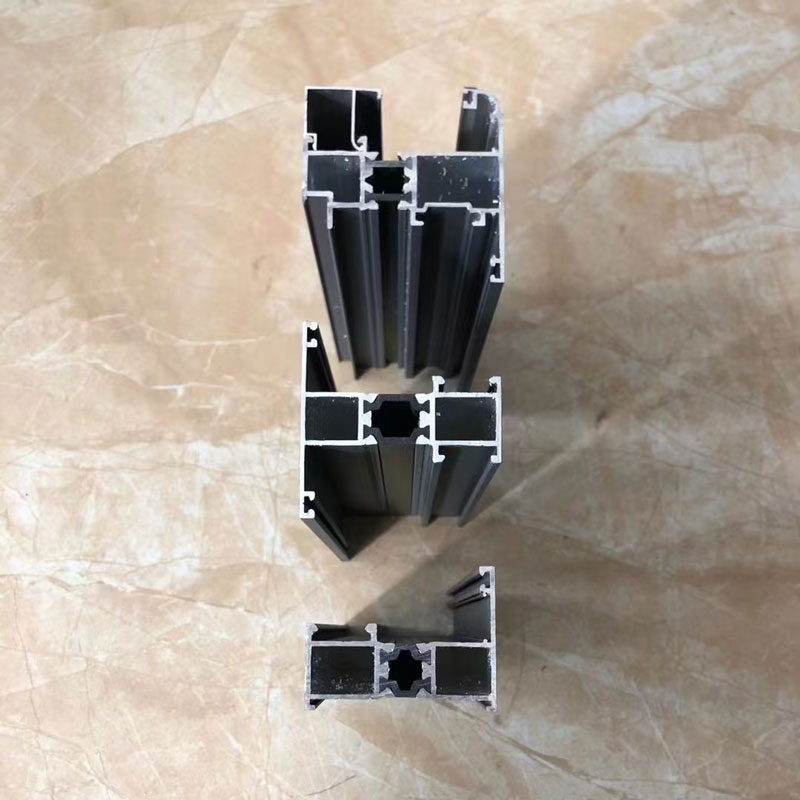

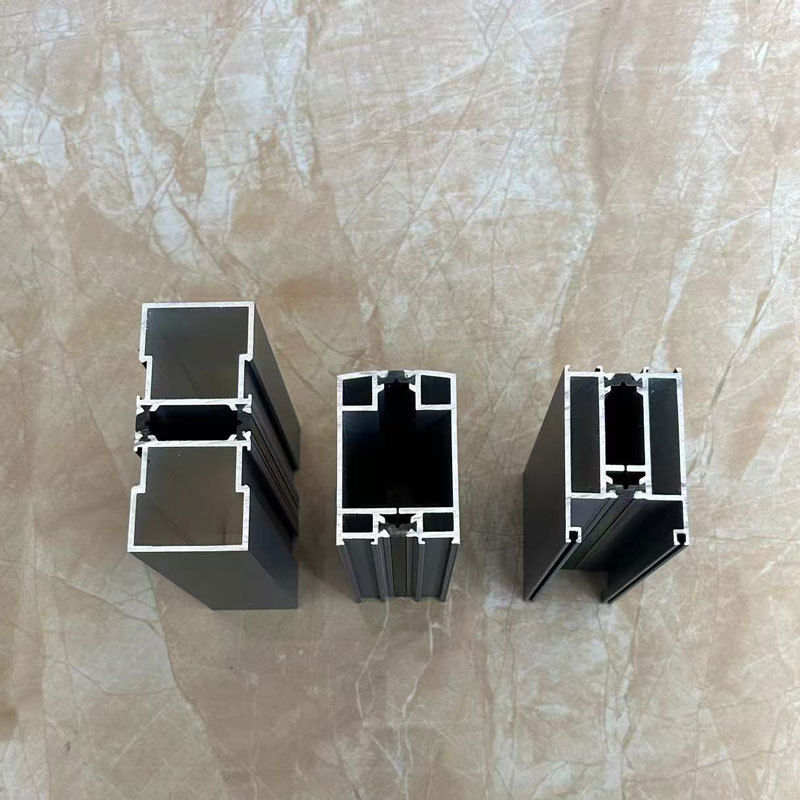

To ensure effective quality control of the production process, employees of each workshop improved their abilities for the self -inspection and strengthened the self -inspection link in the production process. The inspectors of the workshops increased the severity and frequency of inspections, all sizes of the product are carried out in strict accordance with the standards of internal control of the company, and the results of the checks are recorded in detail. In each workshop, strict quality control is carried out, which significantly improves product quality.

Together, this month of quality was successfully completed. Thanks to this event, the awareness of the entire personnel about quality has significantly increased, the level of skill and managerial abilities of employees improved, the goal was achieved and good social benefits were obtained. The measures within the framework of the quality of the quality have significantly improved the quality of our products, and we hope that all workshops will be able to maintain the current good tendency, pay attention to quality and form a good working atmosphere, attaching importance to quality every month and comprehending quality every day to constantly promote the quality of our products to a new level, create a reputation as a company’s quality, build a brand and conquer a strong position in competition in the market.